Ethical Logistics . com

Heavy combination vehicle stability and dynamics

Sourced from Land Transport New Zealand

An introduction programme for drivers of heavy

motor vehicles

Introduction

New Zealand has a high incidence of rollover and loss-of-control crashes for distance travelled

compared with other countries such as the United States and Canada. Rollovers occurred in 29 percent

of the heavy vehicle crashes attended by the New Zealand Police Commercial Vehicle Investigation Unit

between July 1996 and November 1999.

This high number of rollover and loss-of-control crashes reflects New Zealand’s difficult driving

conditions. The country has more bridges, corners and hills per 100 kilometres of road, and fewer

divided highways, than most other developed countries.

Drivers of large vehicles have an obligation to drive considerately and professionally at all times.

Rollovers in single-vehicle crashes involving trucks often reflect the drivers’ poor appreciation of the

general dynamics and stability issues of the vehicle.

The majority of the factors that influence the stability and dynamics of heavy combination vehicles also

influence the stability and dynamics of heavy rigid vehicles.

The basics

Vehicle dynamics:

This term refers to the motion of a motor vehicle and the various forces that act upon the vehicle when

it is in motion.

An often overlooked aspect of the dynamics of motor vehicles is that in the majority of situations a

vehicle has to be moving before the forces acting on it affect its performance. Thus (with only a few

minor exceptions) a person – the driver – must make the vehicle move. It follows then that if the

person in control of the vehicle is making it move then this person should have total control over

whether the dynamics of the vehicle will be a contributing factor in any crash the vehicle may be

involved with.

The laws of nature

Like everything around us, we are all affected by the laws of nature. These laws ensure that:

- we don’t fall off the planet

- if we throw something it will keep going in a straight line away from us

- a person walking into a tree will probably injure themselves but a person running into a tree will

- if you wander onto ice you stand a really good chance of falling over.

These same principles apply to our vehicles and, while they cannot be totally eliminated, they can be

controlled and their effects minimised.

Side wind

Vehicles with high flat sides, such as furniture trucks and

trucks transporting containers, are extremely susceptible to

the effects of cross wind (wind blowing onto the side of the

vehicle).

In conditions of extreme crosswind, road controlling

authorities may issue strong wind warnings for some

stretches of road. When these are issued take note and, if

the warning includes advice not to travel over a particular

area of road – don’t.

Remember also that your vehicle will generate its

own wind as it moves along the road. The faster

you go, the greater the wind forces generated will

be. These forces can be sufficient to blow

motorcyclists over and buffet other vehicles to a

point that the driver loses control, so you need to

be considerate of other road users and slow down.

Speed

The effect of speed on the cornering ability, braking distance and impact forces acting on a vehicle

increase as the speed increases. Cornering forces don’t just double when the vehicle speed doubles,

they increase by four times.

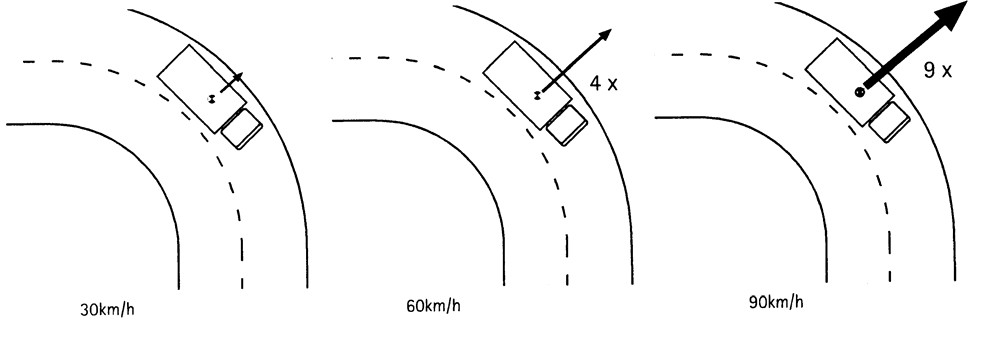

This effect is highlighted in the following diagram.

The arrow in the left-most illustration represents the overturning force acting on a truck in a

30 kilometre per hour (km/h) corner. If the same truck is driven through the same corner at 60 km/h,

the overturning forces will be four times higher (2 x 2 = 4, speed-squared effect), represented by the

arrow in the middle illustration. If the truck is now driven through the corner at 90 km/h the

overturning forces will be nine times higher (3 x 3 = 9, speed-squared effect) than at 30 km/h, as in

the third illustration.

This speed-squared effect has a dramatic impact on the vehicle and its controllability.

Gravity

Gravity creates a force that, in simple terms, attracts everything towards the centre of the earth.

This force is measured as weight and means that a person weighing 90 kilograms (kg) and a truck

weighing 15,000 kg are both attracted towards the centre of the earth with the same speed of

acceleration. If both were free to fall they would accelerate at the same rate, called one gravity (1 g).

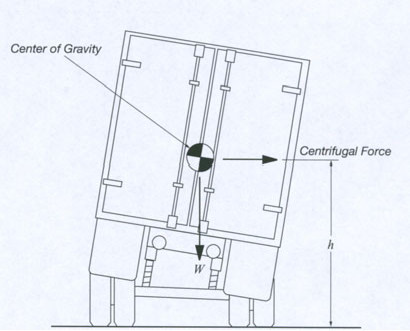

Centre of gravity

Every object affected by gravity has a centre of gravity (CG),

which is the point around which the object, if placed on a

pointed stick in the ground, would be balanced in all directions.

The higher the CG, the more unstable the object (such as a

truck) will be. The closer to the ground, the more stable the

object.

Thus the stability of a truck is largely dependant on the height

of its CG above the ground. If a load is not centred across its

width; the stability will be reduced when cornering.

If the load is not balanced correctly along its length, wheel lock-up during braking becomes a distinct

possibility. When wheel lock-up occurs, the vehicle loses steering control.

Kinetic energy

Kinetic energy is the energy present in any moving object. The heavier and/or faster the object, the

more energy it will contain.

A bullet, for example, is small but extremely fast and has the potential to do a lot of damage over a

small area owing to its kinetic energy. A truck, on the other hand, is relatively slow but is extremely

heavy and has the potential to do a great deal of damage over a greater area for the same reason.

While a bullet’s energy is either absorbed by the target or eventually eliminated by friction as it moves

through the air, the energy in a vehicle is converted to heat by the friction that occurs in the brakes

when the driver applies the brakes.

The effects of kinetic energy increase at the square of the speed – and have a major influence on all

motor vehicles in three particular situations, as explained below.

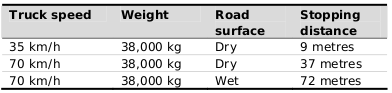

1 Braking

The faster a vehicle goes, the further it takes to stop.

As the table below shows, if a truck’s speed is doubled it will take at least four times the distance to

stop. Longer if the road is wet.

2 Cornering

If a truck enters a corner at 60 km/h, there will be four times more overturning (side) force on the

vehicle than if it had entered the corner at 30 km/h.

3 Impact

The damage to a vehicle (and its driver) at the point of impact in a crash situation will also increase in

proportion to the square of the speed. In other words, double the speed = four times the damage,

triple the speed = nine times the damage. A pedestrian knocked down at 60 km/h will most likely

suffer four times as much damage as one knocked down at 30 km/h.

Friction

Friction is the resistance to motion that occurs when one body or surface moves across another. On a

vehicle the most common points of friction are the brakes, the tyre contact with the road, air

resistance, and engine and transmission components. It is the friction between the tyres and the road

that allows the driving, braking and cornering forces to be transmitted to the road surface.

Friction creates heat. Vehicle braking systems produce large amounts of heat, which has to be

dispersed very quickly. The secret to a good braking system its ability to remove that heat quickly and

efficiently.

The faster a vehicle is travelling, or the heavier it is, the more heat the brakes generate in bringing the

vehicle to a stop.

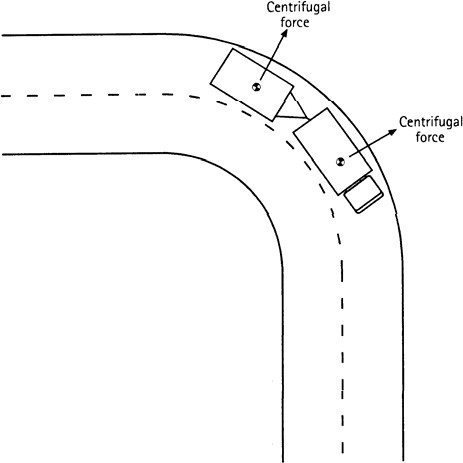

Centrifugal force (overturning or side force)

Centrifugal force occurs when a moving object, such as a vehicle, changes direction. This is the same

force that causes passengers to slide across the seat and

loose freight to slide across a deck when cornering at higher

speeds.

The weight of a vehicle means that when it is travelling in a

straight line it will try to continue in that direction, even

when the driver turns the steering wheel.

Changing direction causes the vehicle’s weight to move to

the outside of the turn which, unless the driver controls its

speed, can lead to the vehicle rolling over or sliding out.

Centrifugal force is affected by the vehicle speed

and the angle of turn. In other words, the faster

the vehicle is going and/or the tighter the turn,

the more likely the driver is to lose control of the

vehicle and for it to roll over.

Stability

There are many factors influence a vehicle’s tendency to roll over, but the following are the most

crucial:

- the vehicle’s speed

- the height of the centre of gravity

- the type and condition of the suspension

- the type and condition of tyres.

If all these factors are contained within acceptable levels,

the vehicle will remain stable. If they are not, then the

risk of loss of control and rollover will increase.

Typically rollovers occur during cornering (at either high

or low speed) and sudden evasive steering manoeuvres.

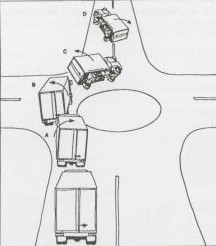

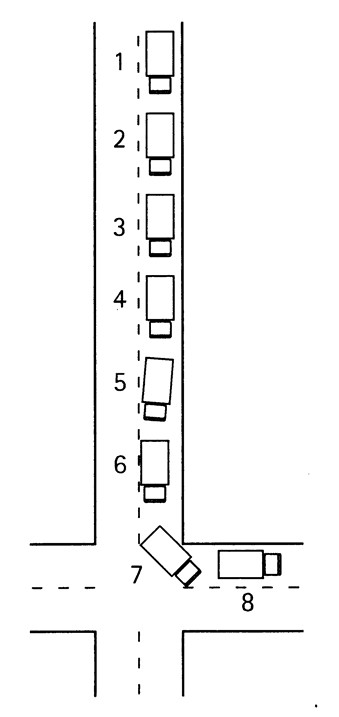

Rollovers at roundabouts

The following is an example of how rollover can occur

at a roundabout even though the truck may be

proceeding straight through.

The driver of a loaded truck intends to proceed

straight through a roundabout. He/she safely

negotiates the left-hand bend at point ‘A’ and the

vehicle rolls to the right. The driver then swings the

steering to the right at ‘B’ to travel around the

roundabout and the vehicle rolls to the left. But this

time it rolls much further than it did at point ‘A’

because the directional changes of the vehicle match

its roll resonance. At this point the load might even

shift, transferring more weight to the left-hand side

of the vehicle, increasing the roll still further and

possibly overturning the vehicle on to its left side at

point ‘C’ as shown. However, if the vehicle is able to

continue past point ‘C’ and the driver then steers to the left, the vehicle will roll back to the right still

more violently and is even more likely to overturn, this time on to its right side at point ‘D.’

This can occur at a surprisingly low speed, speeds which may be quite safe for another type of truck,

even when fully laden. This danger is not restricted to roundabouts; S-bends and violent lane changes

can present a similar hazard.

Evasive manoeuvres

Drivers operating heavy vehicles need to make constant steering corrections, whether to compensate

for simple road undulations and the effects of camber or wind, or when negotiating intersections and

undertaking evasive manoeuvres to avoid other vehicles or obstacles.

These manoeuvres can be at relatively low speed but involve several directional changes (as in a

roundabout) or take place at high speed, as in a steering correction during cornering or changing

lanes. In each of these situations there is transfer of weight from one side of the vehicle to the other.

With a heavy combination vehicle the effect of changing direction at higher speeds raises a number of

additional issues to those normally experienced when driving a rigid vehicle. One of the most

significant of these is rearward amplification or ‘cracking the whip’

Rearward amplification

This only applies to heavy combination vehicles where in the total length of the combination there is

more than one articulation (pivot) point. For example, a truck and trailer combination has a pivot point

in the draw bar coupling; a ‘B’ train has two pivot points, one in each turntable where the kingpin is

locked into the turntable jaws.

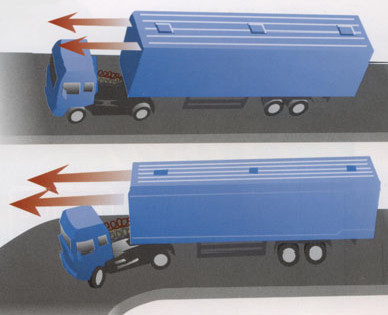

Rearward amplification, or cracking the whip, occurs during a rapid lane change where a relatively

small steering input of the towing vehicle is amplified (increased), through each pivot point. The result

being that the end trailer in a combination can react very violently to the lane change.

Overseas research has demonstrated that cracking the whip becomes a significant stability factor at

road speeds above 60 km/h.

Manoeuvring

Manoeuvring a combination vehicle, particularly at lower speeds, introduces a number of factors of

greater significance than those encountered when manoeuvring a rigid vehicle.

As a general rule, the more manoeuvrable a combination vehicle is, the less stable it is likely to be in

open road driving situations.

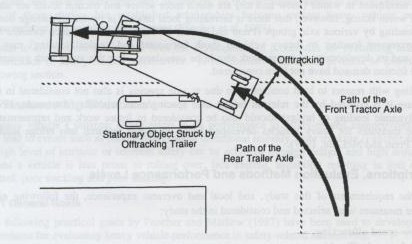

Low-speed off-tracking

When a long vehicle makes a low-speed turn,

at an intersection for example, the rear of the

vehicle may off-track (take a different path)

around the corner than the towing vehicle. In

some situations there can be several metres

difference.

This is shown in the picture below.

Drivers of heavy combination vehicles must

be aware of this whenever they manoeuvre a

vehicle, particularly when the result of off-

tracking could be for the vehicle to come into

contact with another vehicle or a building.

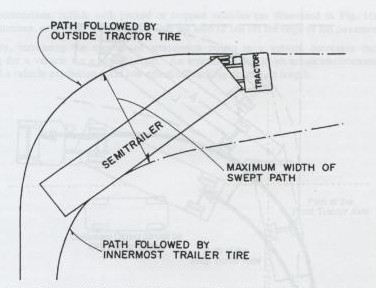

Swept path

When a heavy combination makes a turn, especially

a sharp turn to the left or right, the trailer or trailers

do not necessarily follow in the same path (track) of

the towing vehicle. This is similar to off-tracking.

Swept path is illustrated in the drawing below.

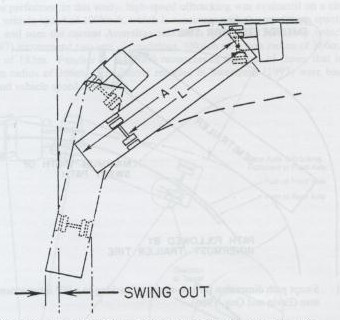

Swing out

Associated with swept path is swing out. This is the effect

that is caused by the rear of the trailer (its rear overhang)

taking a path outside that of the rest of the vehicle. This is

illustrated in the drawing below.

Drivers of combination vehicles must also be aware of this

effect and make allowances for it when manoeuvring, again

particularly at lower speeds.

Trailer yaw

Any vehicle that is being towed by another vehicle will

experience some degree of sway from side to side (yaw). The amount of yaw experienced by the

towing vehicle is influenced by a number of factors, but speed and loading conditions are the most

crucial factors. Yaw is generally explained as the way in which the trailer trails the towing vehicle.

Once a trailer has started to yaw (sway from side to side) it can quickly develop into an uncontrollable

situation and can easily result in the vehicle overturning. A safe method of reducing trailer yaw is to

slow down but do not use the brake as this could easily develop into a jack knife situation.

Trailer yaw should not be confused with rearward amplification. Trailer yaw is a swaying motion that

can be encountered on straight roads and can develop without any steering input from the driver.

Rearward amplification on the other hand is a result of a lane change or similar manoeuvre where the

driver alters the path of the vehicle through the steering.

Rating different types of combination vehicles

There are two common types of combination vehicle in use on New Zealand roads: truck and trailer;

and semi-trailer including ‘B’ trains. A third type common some years ago was the ‘A’ train, but many

of these had an inherent stability problem, which has resulted in them being progressively withdrawn

from service.

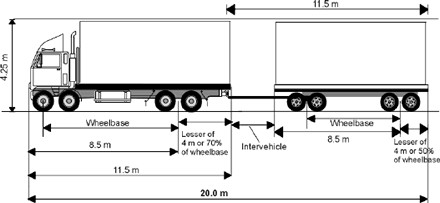

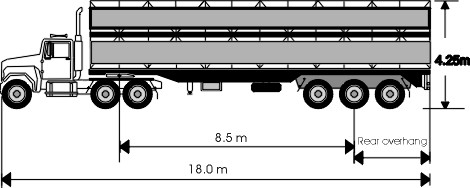

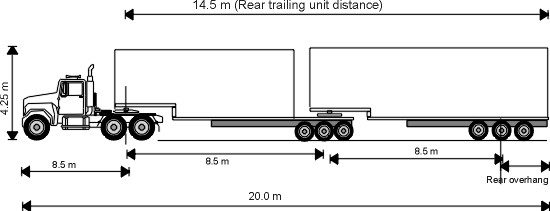

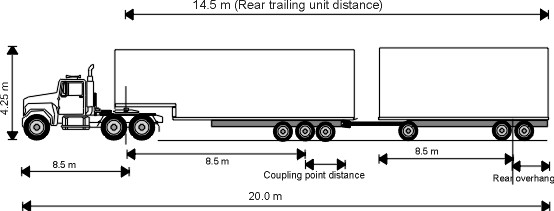

The drawings below show typical examples of common types of heavy vehicle combinations that can

be found in New Zealand, together with their relevant maximum dimensions

Truck and trailer unit

Semi-trailer

‘B’ train (two semi-trailers)

‘A’ train (one semi-trailer with a full trailer behind)

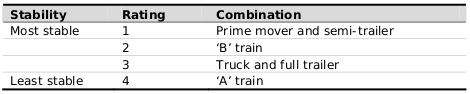

On a stability rating chart, and taking all relevant factors into consideration, the above combination

vehicles can be rated against each other as follows:

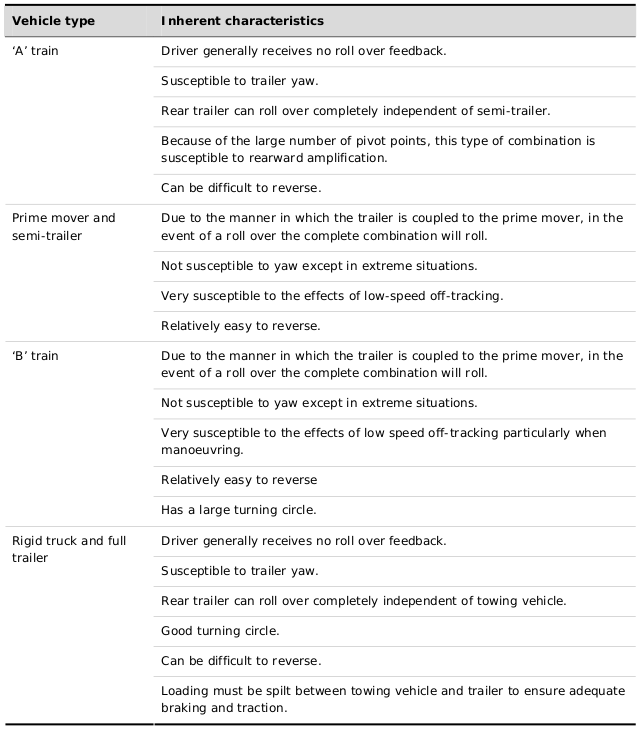

Notwithstanding the above, each type of combination has some inherent characteristics that drivers

need to be aware of when they are operating a vehicle of the particular type.

Vehicle and load factors

Vehicle inspections

A number of the items that must be checked during a daily inspection of a vehicle can directly affect

the stability of that vehicle. Some of these are outlined below.

Tyres

Tyres transmit all the driving, braking, steering and cornering forces from the vehicle to the road. They

also play a crucial role in maintaining stability. Tyres that are not inflated to the correct pressure will

wear out much more quickly. Research has shown that the life of a tyre that is consistently operated at

a pressure 20 percent below what it should be can be reduced by at least 25 percent.

Tyres must be checked for compatibility, tread, inflation and damage at the commencement of the day

or driving shift and spot checks of the tyres condition should be carried out during the shift. Tyre

pressures should be checked with a gauge at least weekly.

Suspension

The suspension supports the entire vehicle’s weight and isolates the vehicle and the load from road

shocks.

While air suspension can provide superior stability and handling to traditional leaf springs, all

suspension components must be checked for damage or distortion regularly.

Brakes and steering

These must be checked prior to moving off. Any problems that are found must be reported and

immediately rectified.

Excessive ‘freeplay’ in the steering will result in difficulty maintaining a correct and proper driving line.

As a general rule, any free movement at the rim of the steering wheel must not exceed 1/5 of the

steering wheel’s diameter. For example, for a steering wheel that has a diameter of 380 mm, the free

play must not be more than 76 mm. If it has more than that, you should have it investigated

immediately.

Hub temperatures can be checked as a way to identify whether individual brakes are binding or,

alternatively, not operating at all. One brake out of adjustment can add metres to the stopping

distance.

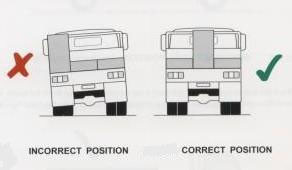

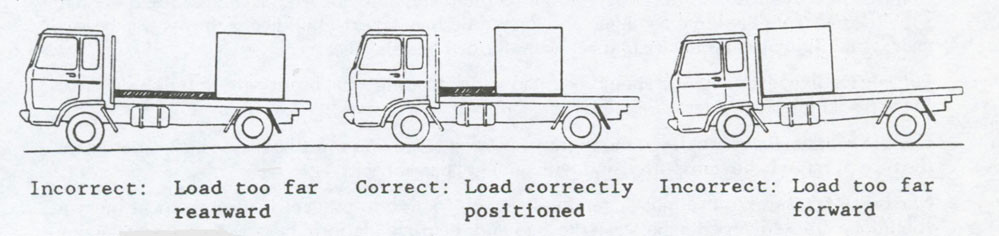

Load placement

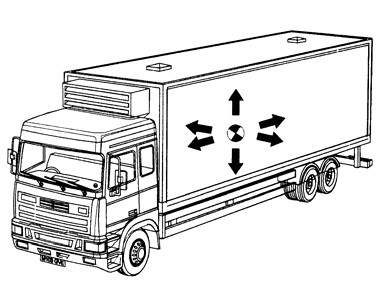

Load placement and load security are key factors in

vehicle handling and dynamics. Drivers must make

sure there is enough weight over all axles to provide

adequate brake balance, directional stability and to

ensure individual axles are not overloaded.

The load must be distributed evenly across the vehicle

as shown below. When offloading freight, it’s

important to consider redistributing the remaining

cargo to maintain the loads balance across the vehicle

deck.

Heavy items should be placed to the bottom of the load so that the CG remains as low as possible.

Load transfer

When a vehicle is braking, the weight of the load is moved towards the front of the vehicle. This can

increase the weight on the front axle, at the same time reducing the load on the rear axle(s). In severe

braking applications, the load on the rear axle may be removed almost completely and the vehicle will

skid sideways, making the vehicle out of control. This may be particularly pronounced on wet or

slippery roads or roads where the surface is not stable, such as on gravel.

It is for this reason that braking should always be smooth and steady and not aggressive.

Trailer loadings

The government has imposed maximum loadings that can be placed on heavy combination vehicles.

Generally speaking, the gross mass (weight) of the rearmost trailer in a combination vehicle set must

not exceed 1.5 times the gross mass of the towing vehicle. For more detailed information on this you

should consult Land Transport Rule: Vehicle Dimensions and Mass 2002.

Dealing with specific types of load

There are a number of types of loads that require special consideration in regard to their stability.

Some examples of these are listed below.

Tankers

Although there have been many improvements to tanker

design over the years to improve their on-road stability,

such as lowering the height of the tank, these types of

vehicle still require special skills because of the nature of

the freight they are transporting.

A liquid in a tank will

surge (that is move back and forward as the vehicle

accelerates and slows down) so drivers of tankers must

be constantly on their guard to ensure that this

movement does not override their actions in controlling

the vehicle. To overcome this problem ,some tankers

(those that carry only a single product at a time) may

be fitted with baffle plates to reduce the amount of

surge, while tankers that carry a range of products in one load will have a series of self-contained

compartments, effectively mini tanks inside a common shell.

Bulk dry goods

These types of vehicles often have an inherent high CG. The load can shift and, because of the nature

of the load, once it has shifted it may not flow back to its original level.

Hanging meat

Meat hanging in a chiller body can be a very unstable load. Not only will the load have a high CG, but

the load can act like a pendulum and swing from side to side. This pendulum effect can be very

noticeable on winding roads or when executing sharp turns at speed.

Livestock

Livestock can move around, even in approved stock crates. The effect of this can be reduced by

keeping animals bunched together, but even then the animals may lean over when the vehicle is going

around a corner, altering the CG.

Tip trucks

Particular attention must be paid to tip trucks, especially

when they are being moved with the hoist up, such as

when spreading road metal.

It is not uncommon for loads in tip trucks to stick to the

sides of the dump body, causing a weight transfer to one

side, and when this happens the vehicle may tip over.

Load security

The Truck loading code sets minimum standards for load restraint and operators must familiarise

themselves with it. These standards are designed to prevent load shift under normal operating

conditions, including braking, acceleration, cornering and movement over uneven ground.

Any load that shifts will decrease vehicle stability dramatically, particularly during braking and

cornering. Any loads positioned more than 100 millimetres away from the curtains or sides of a vehicle

must be restrained in accordance with the Truck loading code, to prevent load shift during cornering.

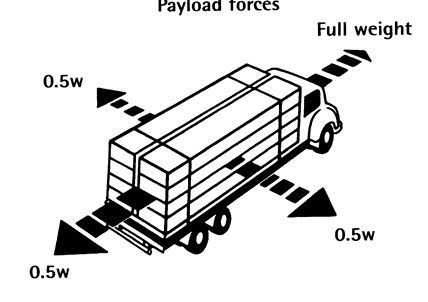

Loads carried on a vehicle must be restrained according to

the following basic rules. Restraints must:

- be able to take the full weight of the load in a

- be able to take half the weight of the load in a

- be able to take half the weight of the load in a

- prevent vertical movement.

The responsibility for loading the vehicle correctly, including making sure it is secured to the minimum

requirements, as shown in the Truck loading code, rests with the driver. The responsibility starts at the

time of loading. Placing loads that increase the height of the vehicle’s CG or shift it off-centre (closer to

one side) will reduce the vehicle’s stability and dramatically affect its handling.

Drivers of vehicles with loads that have a high CG must drive more carefully, especially around curves.

Load security legislation

The Land Transport Act 1998 contains the load security legislation that is administered by Land

Transport New Zealand and enforced by the NZ Police. It provides strict liability for offences involving

insecure loads and loads falling from vehicles. Offences attract fines for an individual of up to $2,000

and a licence may be disqualified for a period as the court thinks fit. The maximum fine for a body

corporate is $10,000.

Load distribution and arrangement on vehicles

- The first priority with any load is to keep within the maximum legal weight limits and vehicle

handling of the vehicle is not impaired. If the load cannot be placed against the headboard,

baulking should be used or twice the strength of lashings are required.

- The load should be spread to keep the centre of gravity as low as possible. Where the load is

to give correct axle distribution and an even weight distribution over its floor area.

- In order to maintain lateral stability, the centre of gravity of the load should be on, or as near as

centre line of the vehicle than at the sides.

- Throughout the journey, at every stop, (including after a rest stop) the load should be checked

may lead to damage of the load or loss of security

Rated strength of vertical securing devices for rigid loads on heavy motor

vehicles

A Combined rated strength = 2W

Securing devices (lashings) have a combined rated strength of at least twice the weight of the load,

where not loaded against a headboard.

B Combined rated strength = W

Securing devices (lashings) have a combined rated strength of at least the weight of the load, where

packets are loaded against a headboard, such that the top packets have at least 150 mm supported.

C Combined rated strength = 11⁄2W

Securing devices (lashings) have a combined rated strength of at least one and a half times the weight

of the load, where lower packets are supported by a headboard but upper packets are not supported

by at least 150 mm.

Failure of the load restraint could result in the load developing sufficient momentum, if allowed to

slide, to demolish the headboard or other abutment with potentially serious consequences.

Anchor points

Traditional rope hooks or rings, and the method by which they are attached to the vehicle structure,

cannot be relied upon for the restraint of other than light loads. For this reason, platform vehicles in

particular should be equipped with load anchorage points, so designed and integrated into the

structure that the maximum forces likely to be imposed on them are transmitted to the main chassis

frame of the vehicle. It is common practice to utilise the coaming tie rails and, in this case, it is

necessary to tie in the vicinity of the cross member and tie rail junctions to prevent distortion of the tie

rail.

Each anchor point must have strength at least equal to the rated strength of the lashings secured.

Loose bulk loads

Loose bulk loads can generally be described as having a nature which does not readily lend itself to

any form of packaging or containerisation, eg sand, aggregate, shingle, rubble, rubbish, asphalt and

other similar materials.

Clearly, the loading and securing of such loads do not pose the many problems associated with general

freight, but nevertheless they do have security problems peculiar to themselves.

Basic safety principles

- The maximum vehicle and axle weights must never be exceeded.

- Loose bulk loads that are liable to fall from the vehicle, and which do not have a tarpaulin fitted,

transported. If the load is heaped to its own natural ‘angle of repose’, this could result in load

shedding due to the vehicle’s movement.

- Doors to bulk bins must be closed to avoid loose bulk loads from being blown out.

- As loads normally rely upon the vehicle body for restraint, it becomes extremely important to

always secure and that these and the body are in sound condition.

- Loose bulk loads should be covered with a tarpaulin, netted or sheeted as appropriate whenever

Driver factors

Steering

It is important to have two hands on the steering

wheel whenever it is possible. This applies not only

during turns and cornering but also when travelling on

straight roads. A driver who adopts a relaxed, two-

handed steering style responds more readily to normal

vehicle movement than one who consistently leaves

one hand off the wheel.

The effects on vehicle handling that occur as a result of

the steering actions of the driver must not be

underestimated, particularly by those who operate

vehicles carrying high-CG loads.

The system of vehicle control

When negotiating intersections, roundabouts and other

potential hazards, such as road works, railway crossings and crash sites, it’s important to control the

vehicle’s speed and side-cornering forces before entering the site.

Drivers who use the system of vehicle control will be concentrating on potential trouble spots, not on

the brakes and gear lever.

While the system of vehicle control does take some getting used to, once perfected it produces an

unrushed, deliberate and safe driving style that reduces the risks, particularly at intersections and even

more so at roundabouts, where these changes in direction can occur, and vehicles carrying high-CG or

‘live’ loads often come to grief. In these situations the combination of road camber and running trailer

wheels onto kerbs can make the stability problems even worse. The system of vehicle control is

explained below.

1 Course

- Know where you are going and put the vehicle in the correct place on

2 Mirrors

- Check behind the vehicle and along both sides.

3 Signal

- Indicate your intentions for at least three seconds before you carry

4 Brake

- Adjust your road speed early so you can downshift.

5 Gears

- Change down, and repeat the process if necessary, so that you are in

6 Mirrors

- Check your mirrors again.

7 Execute

- Carry out the manoeuvre.

8 Accelerate

- Accelerate away from the turn or hazard.

A very cautious and planned approach to corners is always necessary.

Vehicle dimensions and dynamics

Track

The distance between the centres of each tyre on an axle is known as the

track. The wider the track, the better the stability of the vehicle will be. In

other words the wider the vehicle (within the maximum permitted vehicle

dimensions), the more stable it will be. This results in better handling and

improves the overall dynamics of the vehicle.

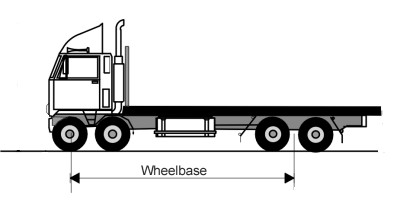

Wheelbase

The wheelbase of a rigid motor vehicle is the distance between

the centre of the rear axle(s) and the centre of the front axle.

In a twin-steer vehicle the wheelbase is measured between the

centre of front (foremost) steering axle and the centre of the

rear axle(s).

The length of a vehicle’s wheelbase is major factor in the manoeuvrability of the

vehicle. The longer the wheelbase, the less manoeuvrable the vehicle is likely to be.

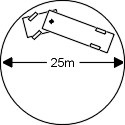

All motor vehicles in New Zealand must be able to complete a 360-degree turn,

both to the left and to the right, within a circle with a wall-to-wall diameter of

25 metres. The only projections which can be outside this circle are collapsible

mirrors. It is for this reason, to improve manoeuvrability, that vehicles used in

areas where manoeuvrability is important, such as rubbish collection, often have

their front, steering axles moved backwards. This is called an offset front axle.

However, moving the front axle backwards can place an additional load on the front axle and upset the

balance of the load between the front and rear axles, thus affecting brake balance and load transfer.

Overhang

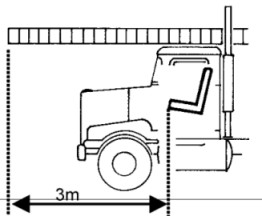

Overhang in either the front or rear will also affect the

manoeuvrability of the vehicle. In New Zealand front overhang is

measured from the front edge of the driver’s seat (in its rearmost

position) to the foremost point of the vehicle or its load. The

maximum permitted front overhang is three metres.

When front overhang is excessive, the part of the load that is

overhanging the vehicle will travel in a wider arc than that taken by

the rest of the vehicle and may come into contact

with a vehicle in the other driving lane or even a

building on the other side of the road.

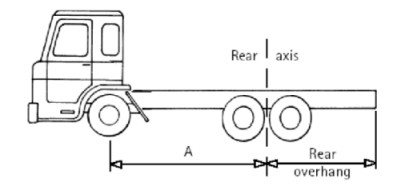

Rear overhang means the distance from the rear

axis to the rear of the vehicle or its load, whichever

is greater. For a heavy rigid vehicle, in which the

rearmost axle is a non-steering axle, the maximum

rear overhang is either 4 metres or 70 percent of

wheelbase (A in the diagram), whichever is lesser.

The affect on the manoeuvrability of a vehicle with excessive rear overhang is similar to that with

excessive front overhang, that is, the extra length of the load will swing wide and may come into

contact with an object on the other side of the road or a vehicle travelling in the another lane.

Cornering

No two corners are exactly the same, so road controlling authorities

sometimes provide an indication of a corner’s severity by using advisory

signs.

These signs often include a recommended speed and a diagram of the

corner’s line. The recommended speed is set for cars and not trucks, so in

most circumstances the posted speed will be too high for a truck to safely

negotiate the curve. To safely go around the bend in a truck the speed of the

truck should be at least 10 km/h lower than what the sign indicates.

For example, the signs on the right indicate that the curve ahead has an

advisory speed limit of 65 km/h. For a truck to safely go around this curve it

should be going no faster than 55 km/h.

Feeling the uncertainty

Drivers of vehicles who have been in rollover or had severe loss of control situations will often not have

had any sense that the vehicle is about to go out of control until it happens. By this time it is often too

late to take any corrective action. Some drivers however may recall sensing a load shift immediately

before loosing control of the vehicle and will often blame this as the cause of the crash. However,

investigations have found that often the shifting load was a result of excessive vehicle tilting, resulting

from the driver losing control of the vehicle, and not the cause of it.

By far the most important aspect of dynamics control is the driver’s response to corners. While every

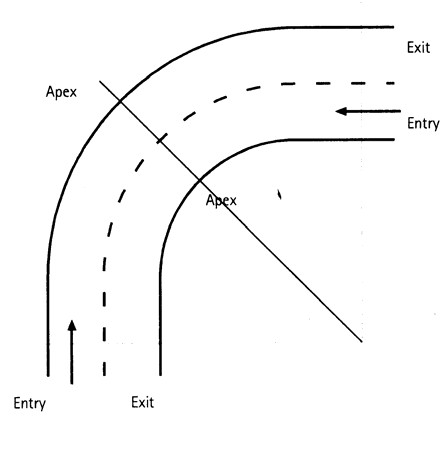

corner is different, each has three definite points.

1 Entry. This is where the driver begins to turn the

steering wheel to enter the corner. At this point the

driver must have completed all deceleration, braking

and downshifting. They should be at, and

maintaining, the desired speed as they enter the

bend.

2 Apex. This is the point where the vehicle is closest

to the inside of the turn. The driver should maintain

the entry speed to this point and now start to slowly

accelerate. The steering line should now be

completed.

3 Exit. The driver should have accelerated from the

apex to this point, which is where the vehicle returns

to a straight line.

Vehicle rollovers normally occur between the apex

and the exit of a corner as a result of excessive speed or braking. When towing a trailer, the prime

mover must pull the trailer through the bend, not be pushed by it. This can only be achieved with the

cornering technique. Cornering stability will be improved, and the effects of centrifugal force reduced,

if the correct cornering line is also applied.

Summary

It is a driver’s responsibility to understand how the dynamics of a vehicle affects the way the vehicle

handles on the road.

Drivers need to:

- acquire a basic understanding of vehicle dynamics

- apply the correct driving techniques to manage the numerous forces at work

- ensure their vehicle speed reflects the driving conditions

- consider the effects of loads and the ever-changing road conditions

- familiarise themselves with the effects of speed, weight and cornering.

Backlinks: Transportation

If you would like to get in touch, I can be reached at